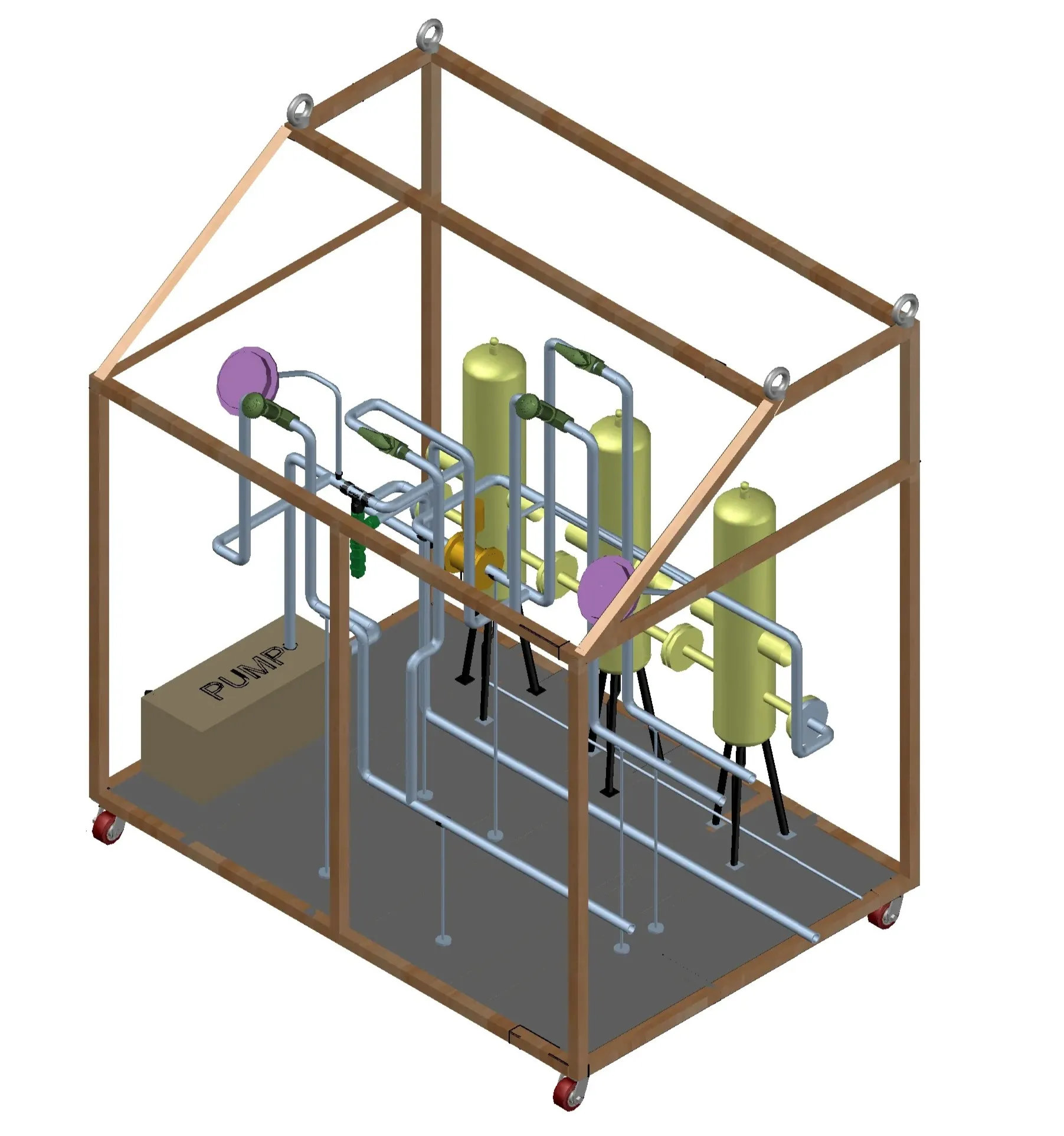

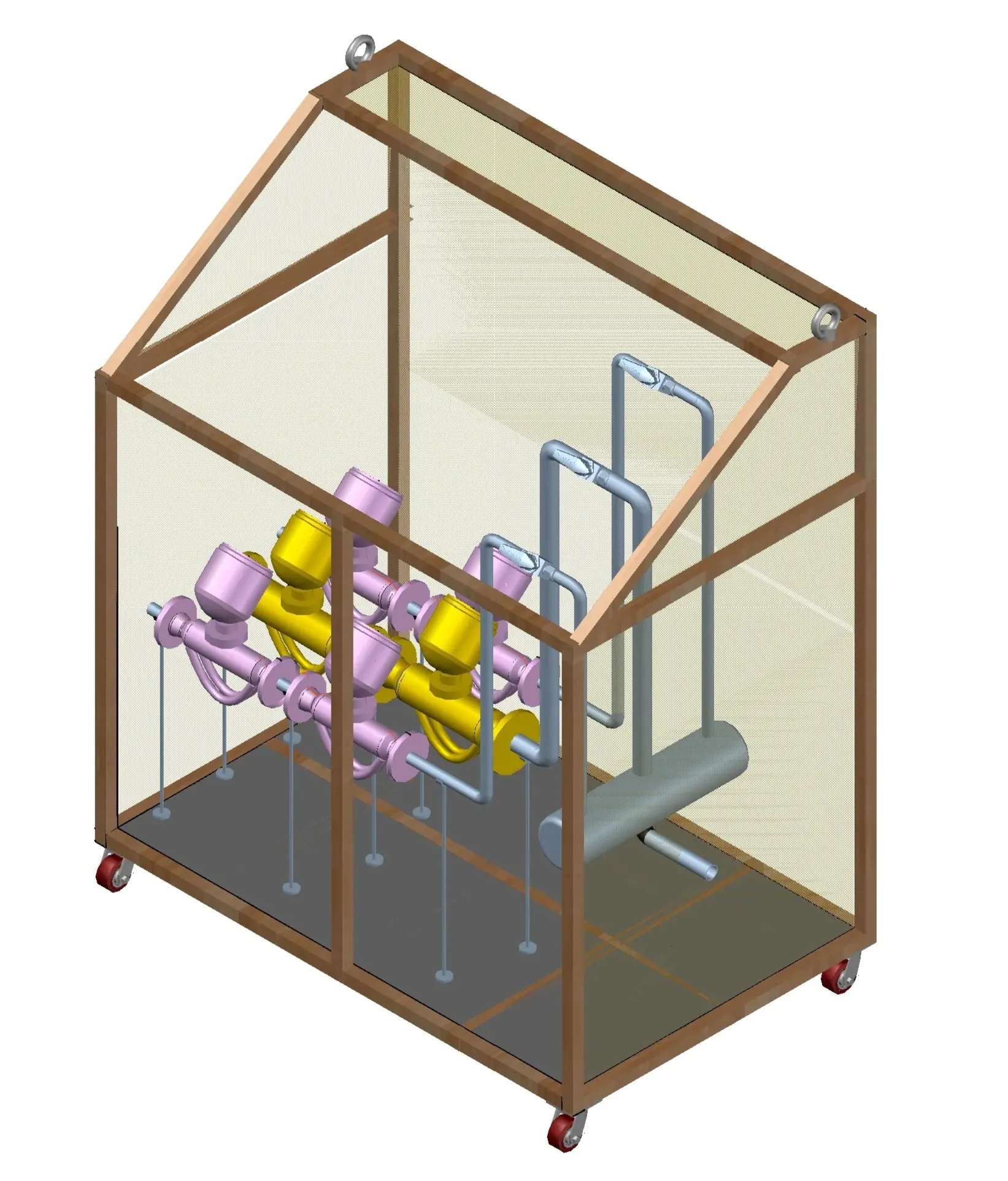

Skid Systems – From Chemical Dosing to Precision Metering

Product overview :

At Maxima Automation, we specialize in the design and fabrication of custom-engineered skid systems, including Chemical Dosing Skids and Metering Skids, tailored for diverse industrial applications. Whether you're controlling chemical injection in a water treatment plant or measuring fuel transfers in an oil terminal, our skids are compact, reliable, and automation-ready.Our turnkey solutions simplify integration, improve process reliability, and reduce on-site installation time. Every unit is factory-tested for performance, safety, and compliance—built to meet the highest industry standards.

Why Choose Maxima Skid Systems?

- Custom-Engineered for your media type, flow rate, pressure, and site layout

- Plug & Play unitsfully assembled, tested, and ready for quick deployment

- Automation-Ready, supporting SCADA, PLC, and IoT interfaces

- Corrosion-Resistant Materials (SS316, PVC, HDPE, etc.) tailored to media compatibility

- Detailed CAD drawings for design validation, layout planning, and approval processes

- Local Calibration, AMC, and Service Support

Chemical Dosing Skid Highlights :

Our Chemical Dosing Skids provide accurate, controlled dosing for treatment and processing across industries.

Key Features:

- Dosing pumps: Diaphragm, plunger, or peristaltic

- Integrated tanks, agitators, valves, and pipelines

- Flow control, pressure relief valves, NRV, and calibration columns

- Level, pressure, and pH sensors (optional)

- Modular, compact layout with IP-rated enclosures

Applications:

- Water & Wastewater Treatment (e.g., chlorine, alum, polymers)

- Cooling Towers & Boilers

- Oil & Gas – Demulsifiers, corrosion inhibitors

- Food & Beverage – Sanitation dosing

- Chemical & Pharma – pH balancing, catalyst dosing, CIP

Metering Skid Highlights :

Our Metering Skids are designed for high-precision flow measurement of liquids and gases.

Key Features:

- Flow meter types: Coriolis, Ultrasonic, Electromagnetic, Turbine, PD

- Pressure/temperature compensation

- Filtration, air eliminators, flow conditioners (optional)

- Skid-mounted frames with stainless/carbon steel options

- Digital displays, totalizers, or remote communication

- Integrated control panels (HMI/local/remote)

Applications:

- Oil & Gas – Custody transfer, loading/unloading

- Water Utilities & Distribution

- Chemical & Petrochemical Plants

- Power Plants – Steam & fluid measurement

- Food & Beverage – Ingredient metering

- Industrial Batch Processes

Our Process – End-to-End Support :

- Requirement Analysis Process, media, flow range, control needs

- Design & Engineering – Mechanical, electrical, process integration

- Fabrication & Assembly – All elements integrated on a single skid

- Testing & FAT Flow tests, leak checks, calibration, and validation

- Installation & Commissioning – On-site setup, training, and handover

- AMC & Remote Support – Ongoing maintenance, troubleshooting, and upgrades

Why Partner with Maxima?

- Deep expertise in fluid handling, metering, and automated control

- Rapid turnaround from concept to commissioning

- Factory-built, fully tested units for reliability and safety

- Seamless integration with existing SCADA, PLC, and IoT platforms

- AMC, spare parts availability, and responsive service

📩 Need a Custom Skid Solution?

Whether you require accurate chemical dosing or precise flow metering, Maxima Automation offers fully engineered skid systems tailored to your process, chemical, and automation needs.

📧 Email: maxproposals@maximaautomation.com

📞 Call :(044) 45565025

Enquire Now